- Кратко о компании Основы компании Концепция компании Партнеры Сертификаты Культура предприятия

- Наши услуги Строительный проект Обслуживание и ремонт Производство и изготовление Реконструкции и модернизация Транспортировка и хранение Обработка и торговля

- Управление в компании История компании Ответственность по всему миру

- Центр закупок Стажировка

- Изделия из металла Изделие из алюминия Изделия из меди Изделия с металлическим покрытием Изделия из нержавеющей стали Изделия из углеродистой стали Особый сплав

- Объект строительства Стальной решетчатый настил Стеллаж Стальная конструкция Стальной мост Строительные леса Строительные материалы Химический металл Универсальное решение для проекта

- Контейнер ДФЭ контейнер для оборудования Контейнер для хранения и транспортировки Контейнерное депо Рефрижераторы Береговой контейнер

- Устройство Металоформовочная машина Другие устройства Металлорежущая машина Металлообрабатывающий станок Листогибочное устройство Строительный блок

- Механическое изделие Автомобилестроение Разное Швартовое оборудование Корабельное оборудование Емкость высокого давления

- Электромеханическая система Электрический кабель Автоматизация Распределение мощности Солнечная энергосистема Система релейной защиты Инверсор Производственная линия Система освещения

- Медицинское оборудование Пищевые принадлежности Трахеостомическая трубка Принадлежности по уходу Изделия из литья

- Строительная техника

- EPC проекты

- нефтепровод

- Водопровод

- Газопровод

- Аксессуары для лодок и швартовные аксессуары

- Металла для украшения

- Компоненты трансформаторов

- теплообменная труба

- детали и аксессуары кондиционеров

- котёл

- обрудования для кухни и ванной

- металл для бытовых электроприборов

- оборудование для солнечной энергетики

- Лифт

- Крыша и потолок

- Кабель

- Танк

- Упаковка

- детали и аксессуары машин и обрудований

- Пресс-форма

- Автомобильные детали

- Железнодорожный рельс и подкрановый рельс

- металлическая арматура

- шлифовальный диск

- оборудовании для дорожно-строительства

- Электронные компоненты

- материал для строительства и украшения

- Двери и окна

- Холодильники

- News release Новости металлургической отрасли Новости по механическому оборудованию Новости по проектам строительства Новости о товарах машиностроения и электроники Новости о контейнерах Новости о электрической системе Новости по медицинскому оборудованию

- База данных медиа Видео Изображения Следите за нами в СМИ

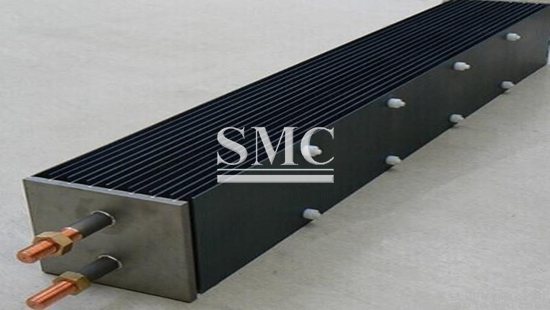

MMO Titanium Anodized Piercing

Coating Thickness:

MMO coating:5~10micron,Platinum coating: 0.5-5micron

The MMO anodes are composed of a titanium substrate coated with a mixed-metal-oxide catalyst. Because the

titanium substrate is naturally passivated by an oxidizing film, the anode remains dimensionally stable over time.

Direct current transfer is accomplished through the mixed-metal-oxide catalyst, which is highly conductive,

and fully oxidized so that the higher current outputs are possible.

Material of MMO Titanium Anodized Piercing:

Gr1/Gr2 Titanium as substrate, mmo coating

Technology of MMO Titanium Anodized Piercing:

Sand blasting,Acid washing and Brush Coating|

Dimension & Shape of MMO Titanium Anodized Piercing:

Different dimension and shape are available, process according to

customized design/ drawing

Working Parameter of MMO Titanium Anodized Piercing:

1) Current density≤2000A/M2

2) Temperature<60°C

3) PH 0.1~14

4) Max content of Fluoride ion is 200PPM

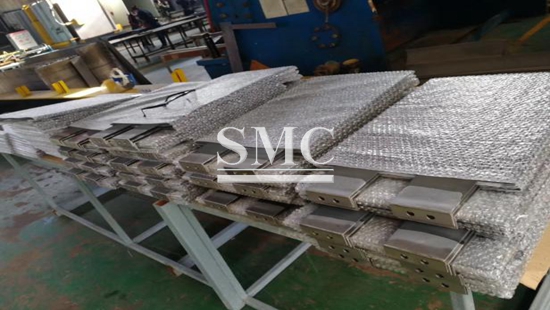

Packaging of MMO Titanium Anodized Piercing:

Plastic or paper as inside, carton or plywood case as outside, or according to client's demand

Advantage of MMO Titanium Anodized Piercing:

1) Insoluble anode, Stable dimension

2) Stable distance of the anode & cathode, Stable cell voltage

3) Low working voltage, save power/electricity

4) High purity of the electroposited material

5) No pollution of the cell

6) Light weight

7) The titanium material is recyclable

8) High property of current efficiency & catalysis

9) Long working life

Application of of MMO Titanium Anodized Piercing:

Electrodeposition for Cu, Zn,Ni,Co,Mn,Pd,Cr,Ag,Au,Rh etc

здесь

для

цен

Мы будем связываться с вами за часов