- Кратко о компании Основы компании Концепция компании Партнеры Сертификаты Культура предприятия

- Наши услуги Строительный проект Обслуживание и ремонт Производство и изготовление Реконструкции и модернизация Транспортировка и хранение Обработка и торговля

- Управление в компании История компании Ответственность по всему миру

- Центр закупок Стажировка

- Изделия из металла Изделие из алюминия Изделия из меди Изделия с металлическим покрытием Изделия из нержавеющей стали Изделия из углеродистой стали Особый сплав

- Объект строительства Стальной решетчатый настил Стеллаж Стальная конструкция Стальной мост Строительные леса Строительные материалы Химический металл Универсальное решение для проекта

- Контейнер ДФЭ контейнер для оборудования Контейнер для хранения и транспортировки Контейнерное депо Рефрижераторы Береговой контейнер

- Устройство Металоформовочная машина Другие устройства Металлорежущая машина Металлообрабатывающий станок Листогибочное устройство Строительный блок

- Механическое изделие Автомобилестроение Разное Швартовое оборудование Корабельное оборудование Емкость высокого давления

- Электромеханическая система Электрический кабель Автоматизация Распределение мощности Солнечная энергосистема Система релейной защиты Инверсор Производственная линия Система освещения

- Медицинское оборудование Пищевые принадлежности Трахеостомическая трубка Принадлежности по уходу Изделия из литья

- Строительная техника

- EPC проекты

- нефтепровод

- Водопровод

- Газопровод

- Аксессуары для лодок и швартовные аксессуары

- Металла для украшения

- Компоненты трансформаторов

- теплообменная труба

- детали и аксессуары кондиционеров

- котёл

- обрудования для кухни и ванной

- металл для бытовых электроприборов

- оборудование для солнечной энергетики

- Лифт

- Крыша и потолок

- Кабель

- Танк

- Упаковка

- детали и аксессуары машин и обрудований

- Пресс-форма

- Автомобильные детали

- Железнодорожный рельс и подкрановый рельс

- металлическая арматура

- шлифовальный диск

- оборудовании для дорожно-строительства

- Электронные компоненты

- материал для строительства и украшения

- Двери и окна

- Холодильники

- News release Новости металлургической отрасли Новости по механическому оборудованию Новости по проектам строительства Новости о товарах машиностроения и электроники Новости о контейнерах Новости о электрической системе Новости по медицинскому оборудованию

- База данных медиа Видео Изображения Следите за нами в СМИ

The major purposes of turning gear operation during turbine startup

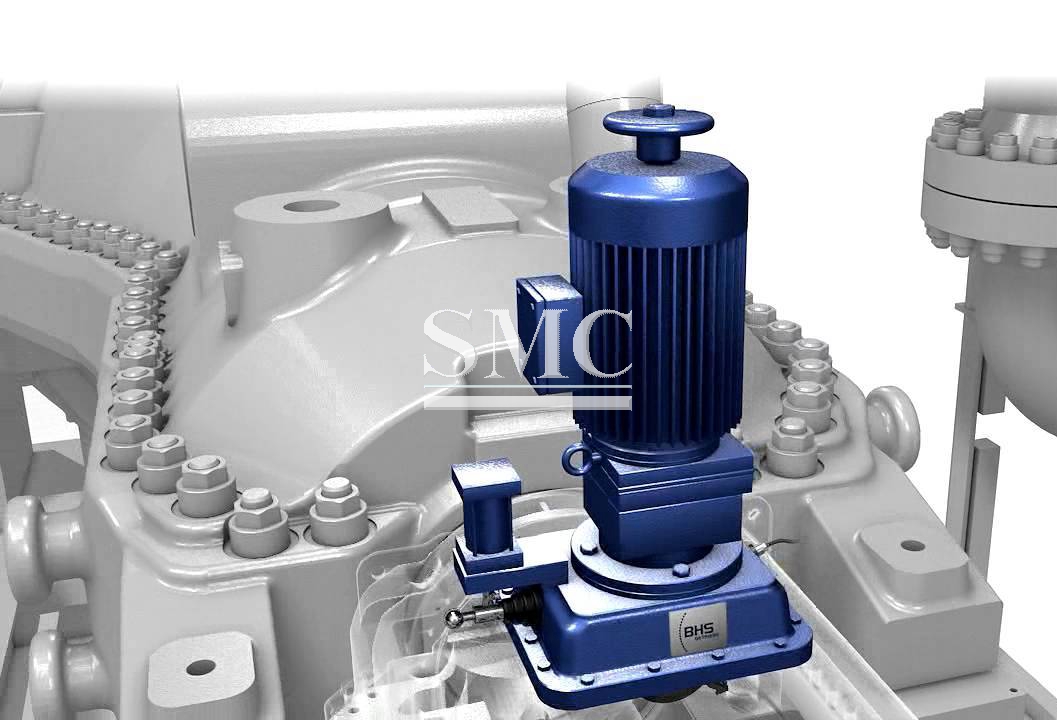

A jacking gear (also known as a turning gear) is a device placed on the main shaft of an engine or the rotor of a turbine. The jacking gear rotates the shaft or rotor and associated machinery (such as reduction gears and main turbines), to ensure uniform cool-down.

Purposes

The major purposes of turning gear operation during turbine startup are:

1. To rollout shaft hogging or sagging before runup is begun

As mentioned in the previous module, any attempt to run up the turbine with an excessively deformed shaft is bound to fail because high vibration would sooner or later force a turbine trip. Meanwhile, the turbine generator would be unnecessarily exposed to increased risk of damage due to high vibration and/or rubbing.

2. To enable uniform prewarming of the turbine generator.

If the turbine generator were prewarmed with the rotor held stationary, rotor and casing hogging would develop due to thermal stratification of . the atmosphere inside the machine as outlined in the earlier turbine courses. This would make runup impossible until the hogging is roiled out.

Operation

To achieve these two objectives, the turning gear is started early during unit startup such that the turbine generator can spend enough time on turning gear. In principle, the duration or turning gear operation must be enough to straighten up the turbine generator shaft such that the HP turbine rotor eccentricity is within the acceptable limit.Moreover,to meet the additional requirements (if any) regarding the minimum time on U1Dling gear that is necessary to equalize turbine casing temperature.

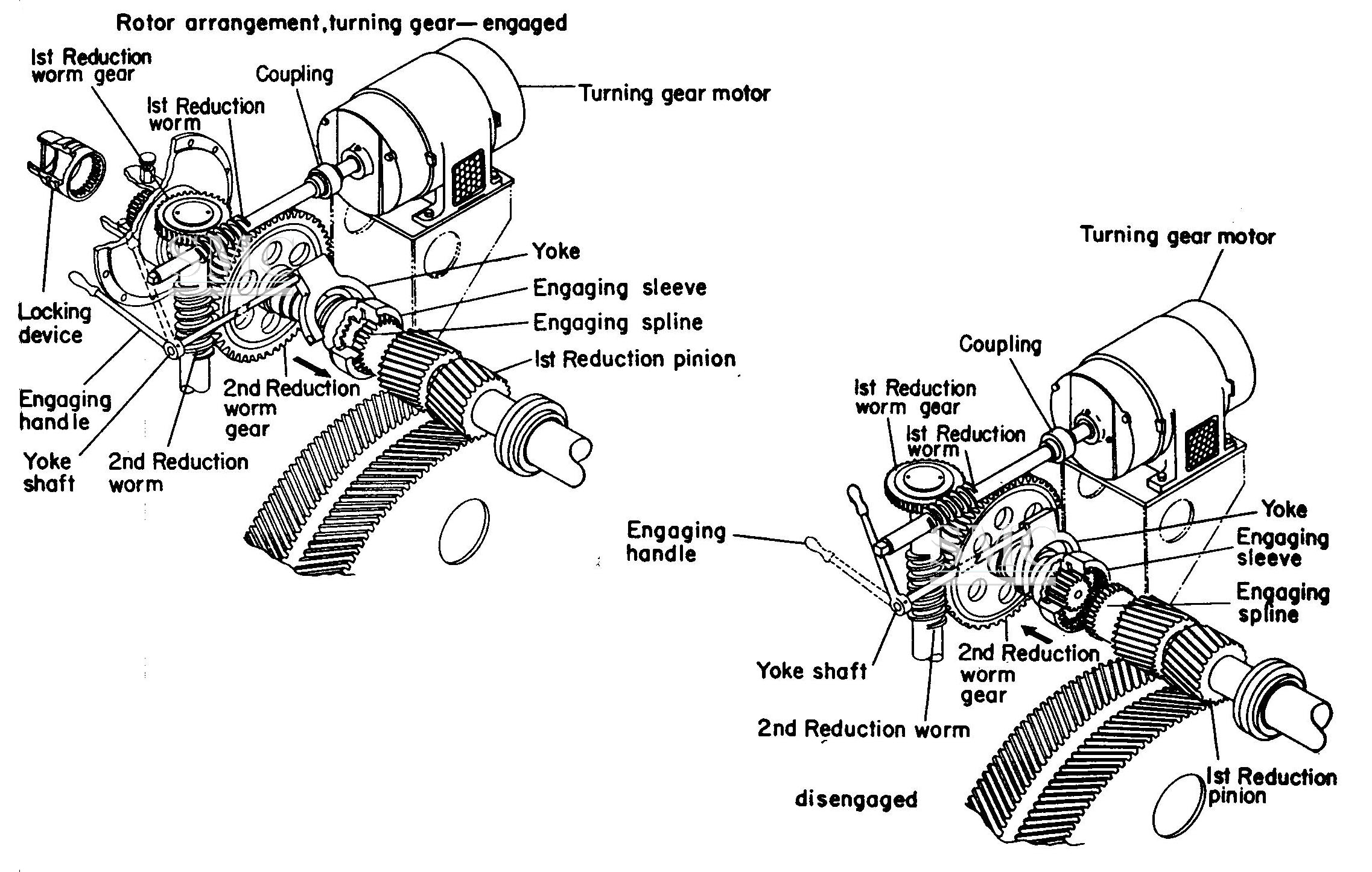

This allows us to make sure that the casing is straight, despite lack of instrumentation that would measure casing hogging or sagging.The required minimum time on turning gear varies from station to station, reflecting the operating experience of the turbine manufacturer. Usually, the minimum time depends on the duration of the preceding shutdown during which the turbine generator rotor was left stationary, and may reach up to 24 hours.When the turning gear is started up, its motor is energized and the turning gear drive is engaged to the turbine generator rotor.

Normally, the turning gear is started manually. but in some new stations, this - along with many other startup activities- can be done automatically by appropriate DCC software.When turbine runup begins, the U1Dling gear disengages automatically as soon as turbine speed starts increasing. The turning gear motor, however, keeps running until turbine speed reaches a certain level· at which the motor switches off automatically. The extended period of motor operation is a precaution taken to make sure the turning gear is available for proper turbine shutdown, should the turbine runup have to be aborted.

Adverse consequences and operating concerns caused by inadequate operation

Failure to turn the turbine generator rotor long enough prior to runup causes the following adverse consequences/operating concerns due to turbine generator operation with an excessively bowed rotor:

1. Increased risk of rubbing damage to turbine generator internals·. Recall that at low speeds rubbing can go undetected because indicated bearing vibration can be misleadingly low despite the abnormal rotor defamation.

2. Increased turbine generator bearing vibrations. As soon as speed is high enough, and particularly while passing through a critical speed range, the vibrations can become abnormally